Defective nematogenesis: Gauss curvature in programmable shape-responsive sheets with topological defects

Abstract

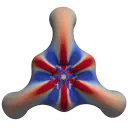

Flat sheets encoded with patterns of contraction/elongation morph into curved surfaces. If the surfaces bear Gauss curvature, the resulting actuation can be strong and powerful. We deploy the Gauss–Bonnet theorem to deduce the Gauss curvature encoded in a pattern of uniform-magnitude contraction/elongation with spatially varying direction, as is commonly implemented in patterned liquid crystal elastomers. This approach reveals two fundamentally distinct contributions: a structural curvature which depends on the precise form of the pattern, and a topological curvature generated by defects in the contractile direction. These curvatures grow as different functions of the contraction/elongation magnitude, explaining the apparent contradiction between previous calculations for simple +1 defects, and smooth defect-free patterns. We verify these structural and topological contributions by conducting numerical shell calculations on sheets encoded with simple higher-order contractile defects to reveal their activated morphology. Finally we calculate the Gauss curvature generated by patterns with spatially varying magnitude and direction, which leads to additional magnitude gradient contributions to the structural term. We anticipate this form will be useful whenever magnitude and direction are natural variables, including in describing the contraction of a muscle along its patterned fiber direction, or a tissue growing by elongating its cells.